With a foundation built on resilience, the story of Midland Steel isn’t just about steel; it’s about vision, survival, and a radical reinvention of an entire industry. Tony Woods, a native of Tipperary, started out in the trade as a steel fixer, learning his craft in London from the age of 15. Today, his brand-new, €16 million smart facility in Portlaoise produces steel-reinforced cages that are ready to use. Their world-renowned FasterFix model enables developers to achieve a 75% reduction in total build time, requiring 80% less onsite labour.

According to Tony Woods, the founder of Midland Steel,

“We started with very humble beginnings. I’m a steel fixer by trade. I come from a bogland in Tipperary. I went to London when I was 15 years of age.” From there, he learnt his trade in terms of concrete and steel.

In 1990, he returned to Ireland and founded a concrete frame company. Over the next decade, his firm became instrumental in building some of the country’s key infrastructure, including stadiums and hotels like the Midlands Park (formerly The Heritage Hotel) in Portlaoise and The Bridge House Hotel.

In the late 1990s, the company faced a critical hurdle: a lack of steel suppliers. In a bold move that would define his entrepreneurial spirit, Woods travelled to a liquidation auction in Zurich and purchased steel manufacturing equipment. “There was a lot of manual labour involved,” he recalled, but the company had taken its first steps toward self-sufficiency.

Midlands Steel establishes in Mountmellick

In 2004, Midland Steel opened in Mountmellick. Tony explains,

“We built the first factory, purpose-built for rebar facilities (rebar facilities are specialised locations where steel reinforcing bars are processed and prepared for use in construction). This service was good at the time in Ireland, because there was a lot of work around. There were lots of houses being built. It’s amazing to say that at that time, we built 90,000 houses. We were an Irish company working in Ireland, totally dependent on Ireland. And from there, we opened a depot in Motherwell in Scotland. In 2008, it was the worst time in the history of the world to open the depot.”

The Crash That Forged a New Path

The global financial crash of 2008 was a near-fatal blow. Midland Steel saw its order book collapse by 95% in just five weeks. The business was on the brink, but Woods made a pivotal decision: he would not lay off a single employee. His core value was to “ensure that the gates of Mountmellick always stayed open.” This commitment to his team forced him to look at the business in an entirely new light;

“August 29. I’ll never forget the date. We lost 95% of our order book in five working weeks. We went from 70,000 tonnes of steel in our facility in Mountmellick to doing 4600 the year after. Our new depot had opened in Scotland, with a lot of investment and not much going on there either. So it was a very, very tough time. Everyday, it was, ‘How much do you not lose, and how can you survive?’

A shift to BIM

This period of adversity became the catalyst for a radical shift. Woods realised that his traditional, labour-intensive methods were no longer sustainable. He began exploring Building Information Management (BIM) and 3D modelling to completely rethink how steel was designed and delivered.

This new approach was tested on a monumental project: the reconstruction of London Bridge Station. Woods proposed fabricating the project’s complex steel columns in his Mountmellick factory in Ireland and shipping them to London. The idea was unheard of, but it worked. What was supposed to be an 18-month job for the contractor was completed instead in a fraction of the time. The ability to drop a fully fabricated column into place in just half an hour, a task that was allotted three weeks, proved the immense value of his innovation.

A Revolution in Automation and Sustainability

Midland Steel’s success at London Bridge wasn’t just a one-off; it was the blueprint for a new business model. Woods saw the challenges in the industry firsthand, noting that the average age of a steel fixer is 56, with only seven new fixers entering the trade for every 100 leaving. The solution was “automation and robotics”.

The company’s in-house team, led by Tony and his son Paul, developed the world’s first robotic welding cell for rebar. This invention transformed the production process, moving away from manual tying and lifting to a more efficient, digital, and safer method.

The Rolex Building, New York – A Case Study

“In the past, we took on a challenging project on Fifth Avenue to build the Rolex building. It was one of the most difficult construction sites in New York, so we decided to challenge ourselves with something that had never been done before. We dug a 21-metre shaft and installed a lift into the 53rd Street subway station. My son Paul helped manage the truck deliveries, even directing traffic on Fifth Avenue to get the trucks in. By using this method, we delivered a pile cap in just two days, a task that would have normally taken seven weeks. This impressive feat caught the attention of other companies, leading to a partnership with Nucor Corporation. That’s how we began working in the USA.“

5th Avenue, New York

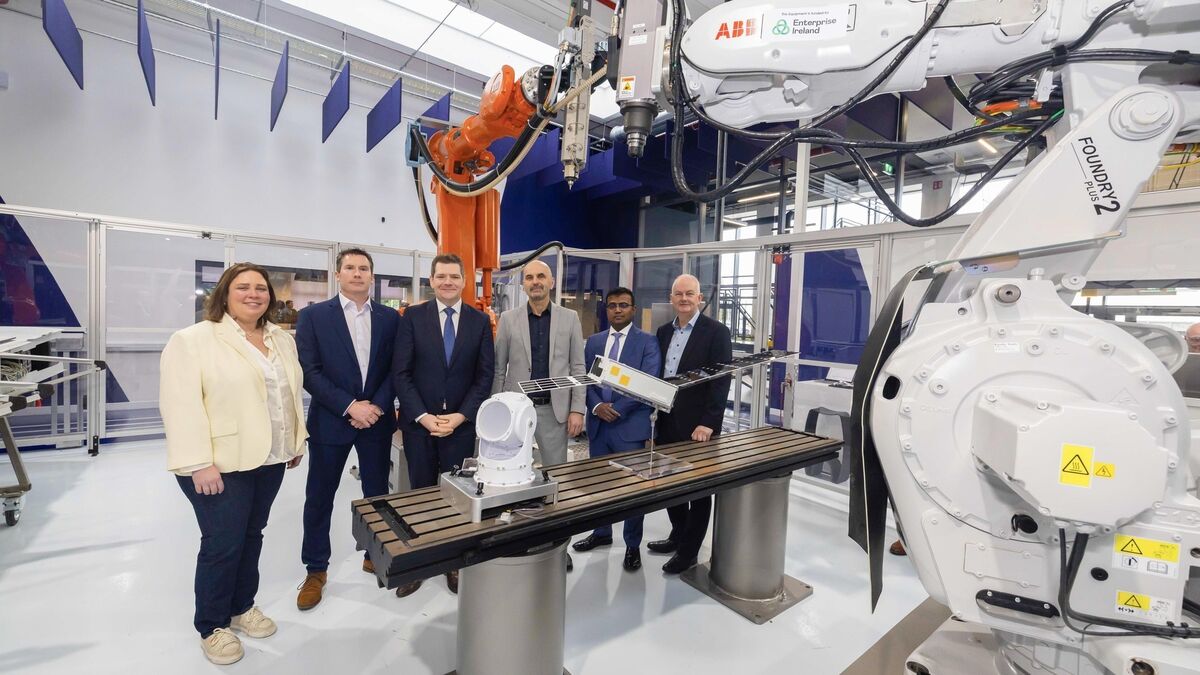

Europe’s greenest rebar facility

This commitment to innovation has also made Midland Steel a global leader in sustainability. The company’s new €50 million smart manufacturing facility in Portlaoise, described as Europe’s greenest rebar facility, is a testament to this philosophy. Woods says the company now guarantees a 0% waste policy on all projects. By utilising its processes, Midland Steel can reduce a client’s on-site carbon footprint by an average of 12.6%.

The “faster fix” model has garnered international attention. For a large semiconductor plant, Midland Steel’s approach reduced the on-site labour needed by 70%, saving the client an estimated €11.7 million. This efficiency has since led to major partnerships and projects across Europe, the UK, and the US, including with industry giants like Nucor and Intel.

“Laois County Council, with John Mulholland, were extremely positive about bringing business and industry smart manufacturing to Junction 17 in Portlaoise. On October the 23rd, 2023, my father was the first man on the site. He’s now 81 years of age, and he’s still pouring concrete. I can’t stop him. He’s an amazing man. He and my mother, God rest her, were my shining light in terms of ambition and vision.”

The Future is Fabricated

Woods’s journey from a young apprentice to a global disruptor is a powerful lesson in resilience and forward-thinking. His company’s new facility can produce enough product annually to build 35,000 homes. It can now produce a complete foundation for a four-bedroom house in just six minutes, a task that traditionally took four hours. Woods proudly states,

“We’ve created in Ireland, in Portlaoise, the world’s best showroom for the disruption of rebar worldwide.”

Midland Steel’s story is proof that even in the face of economic collapse, a commitment to innovation and people can not only save a business but can fundamentally change an entire industry for the better. The company continues to push boundaries, proving that even a 100-year-old trade can be revolutionised with the right blend of ingenuity, technology, and sheer determination.